We are in 2017 AD, the whole world is occupied by capitalists … The whole world? No! A village in the North of Thailand inhabited by invincible people does not cease to resist the invader.

This is where our next journey takes us. It is not about capitalism, but about something much more fundamental. Colorless, odorless, tasteless and without any nutritional value; yet essential to life – clean drinking water.

It all happens in the PunPun Center for Self Reliance. An organic farm in Mae Tang for the preservation of local seed, sustainable life and learning. In principle, the founders resort to a more independent lifestyle by producing organic food themselves, building their own natural homes from clay and experimenting with all kinds of low-tech resources. In doing so, the principles of today’s experts/know-it-all are fundamentally contradicted. It is not about knowledge but about experimenting with knowledge and opening new doors. Errors are not errors in the actual sense, but simply additional learning opportunities. Experts and students learn together on a level playing field; everyone learns from the other. Joint experimentation and joint learning through direct practical applications are the focus here.

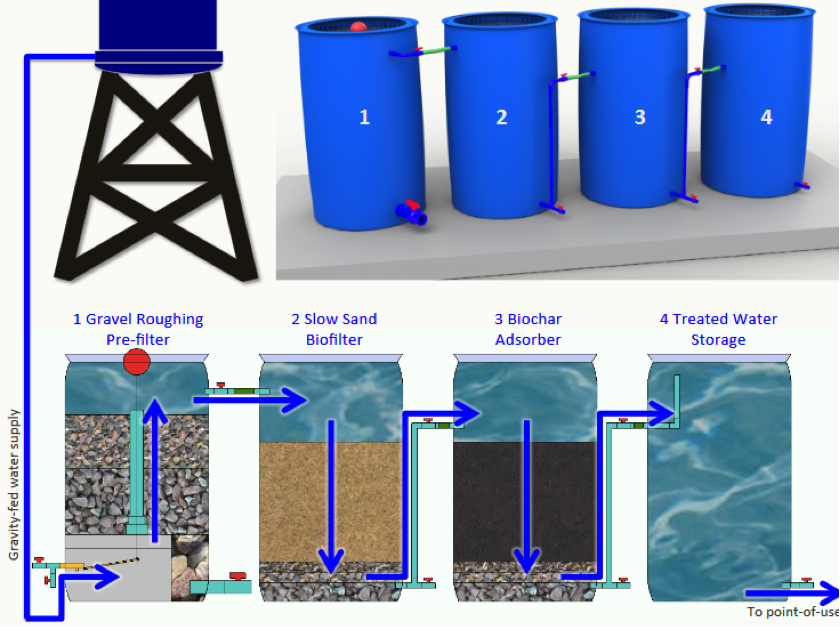

The aim of our trip is a workshop for the construction of a water filter system based on biochar. Up to 300 L (with a small system) or up to 2000 L (with a large system) of clean drinking water can be produced per day. The filter system was developed in cooperation with Aqueous Solutions and all building instructions are accessible to everyone. (http://www.aqsolutions.org/?page_id=927).

Just keep in mind that: the broth from a Thai pond which stands all day in the blazing sun or the polluted water from rivers, which is as a result of so-called SOC (Synthetic Organic Compounds such as Agrochemicals, pharmaceutical residues or contamination from fossil fuels) can be converted into drinking water by an inexpensive water filter for under $ 100. We are thrilled!

In order to get water for our experimental set-up, we had to drill a 9-meter deep well by hand due to lack of rivers nearby. The equipment included only a small diesel generator, a tripod, a garden hose and our workforce.

The next thing after such a day in the sun would simply be to fall into bed. A bell dragged us out of the trance and calls for joint dinner. Through two high clay columns, we stepped into a wide room without windows. This doesn’t mean it is dark. The windows are not installed. A somewhat knee-high table stretches through the entire length of the room and at the edges of which straw mats are spread. The climate in the room was pleasantly cool and light windbreaks caressed the hairs. Faces of people from more than 20 countries look at you, smiling and exhausted. The food of Mae (the Thai word for mother), Dang is certainly the best we have eaten in Thailand. A successful conclusion of the evening was achieved with a philosophical seminar about Jon Jandai on the subject: “Why life is easy. If life is not easy it’s wrong “: D. Simple, authentic, refreshing and recommended. (https://www.youtube.com/watch?v=21j_OCNLuYg)

The next day we started the construction of the filter system. It consisted of 4 tanks filled with different materials for filtering the water. The first is filled with gravel for filtering out coarse impurities. The sand in the second filter removes finer impurities. Upon using the water filter, a so-called biofilm or dirt layer forms on the sand layer and filters out the first biological substances and serves as a pre-filter for the biochar. In the third tank there is the biochar and the fourth tank is designed as a reservoir for the drinking water.

We produced the biochar at night. Technically speaking, biochar is produced by pyrolysis (gasification at approx. 900 ° C) of crushed cellulosic material such as wood, bamboo or maize. It is an incomplete combustion with hardly any CO2 produced. The result is biochar. The heat causes tars and resins from the surface of the material to dissolve and then evaporate. This has two advantages: on the one hand, biological contamination is absorbed in the resulting compartment. On the other hand, the total surface area of the material is increased to 400 m² per gram of biochar (thus 8 million m² or 800 hectares for 20 kg). As a result, the water filters can be operated at full performance for 2-3 years without having to change the biochar.

We smashed the biochar into pieces with a diameter of 15 mm; for almost 2 days

Apart from the ingenious water filter system, PunPun was a unique experience. We cannot describe the atmosphere in words. Everyone should experience it themselves!

Environmental engineer Nate Reents is one of the developers of the biochar based water filters and he was the one who guided us throughout the two weeks showing his passion and sharing his knowledge for low-tech water technologies. He has accomplished many projects in Latin America and Myanmar, where the filters are needed the most. The Pun Pun projects do not just aim at integrating the systems at the Thai Myanmar border but also to teach them how to build them themselves – creating low cost systems based on local materials.

Together with you, we want to support this project. You can round up for donation in our online Shop for harem pants and alternative clothes.

virblatt – think about it.