How our partnership began

Doing business in Thailand is not always easy, especially when it comes to quality and reliability. Often, many sewing shops do not meet the standards we expect in the manufacture of our alternative clothing. That is why we decided to start our own search for an alternative clothing manufacturer that meets our requirements. In Chiang Mai we found a family-run and reliable manufacturer that guarantees fair conditions for his employees. This is how we found Phi Um, whose production has convinced us to this day.

What we like about Phi Um

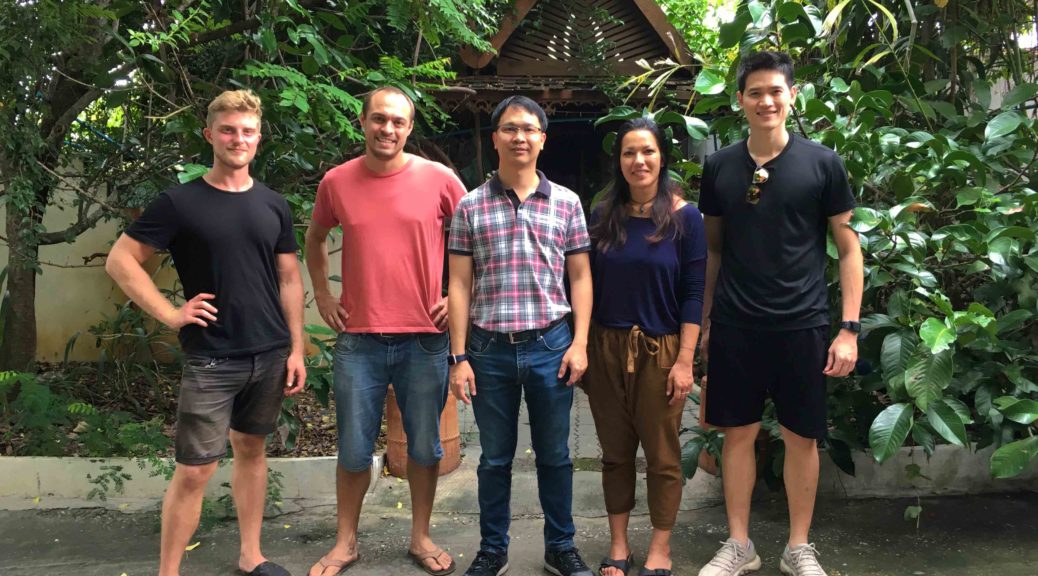

Phi Um runs a medium-sized company completely in family hands. The family members work together with and for their employees. During a visit to the factory, we encountered smiling faces and Thai hospitality. Since our first visit we are warmly welcomed and work in a friendly relationship with Phi Um. Things don’t always run smoothly, but instead of working against each other, we focus on reconciling the goals of both companies together. Therefore, not only he, but also we are jointly responsible for the well-being of his company and his employees. We see this as our claim.

Key data of the company

Phi Um’s company was founded in the 1980s by his uncle and aunt in Chiang Mai, Thailand. Starting small, it now employs around 50 people and has a dyeing, printing and sewing plant. For the most part, the company supplies Japanese customers with standard size clothing. With virblatt there are exciting times ahead, as we have not only started upcycling projects together, but have now also created a sustainable yoga clothing line made of bamboo including bamboo yoga leggings and yoga tops. Phi Um has also recognized that the future of his company lies in sustainable clothing and slow fashion.

Why it stands out

The production of Phi Um convinces primarily by clean premises and family conditions. In addition, the company operates its own dyeing plant, which not only dyes AZO free, but also has a recycling plant for the dyes. This is certified and on site we had the possibility to get an own picture of it.

Phi Um is also distinguished by the fact that both screen printing and digital printing are among his company’s capabilities. With Phi Um we have full control over the coloring, printing and subsequent processing of our clothing. Only in this way can we make our processes more sustainable step by step. We are currently working with Phi Um on a project in which we collect all residues (waste) and integrate them into upcycling products. You can already find a first line under Lappenwerk in our online shop.

Partnership and futurity

Currently we are working on many interesting projects with Phi Um. As already mentioned, we use residual materials to produce a patchwork fabric, which we process in our Lappenwerk line. Our Lappenwerk backpacks combine patchwork fabrics (upcycling) with hand-woven hemp. These two materials are particularly distinguished by their sustainable aspect and make this collection unique. In spring 2018 we will also be launching a yoga collection on which we have been working together for 2 years. This is made of a mix of bamboo (95%) and spandex (5%) and is not only antibacterial and UV-repellent, but also convinces with a great wearing comfort. In doing so, we are breaking new ground and taking a certain risk. But together with Phi Um we are convinced that alternative clothing should not only be unique in its design, but also through sustainability. We are looking forward to many more interesting projects and are grateful for the friendly cooperation in the last years.

Kennziffer: 564738